From injection molding to logo techniques — understand how your slippers are made, step by step.

Select from breathable EVA, soft fleece, or warm faux fur. Tailor your choice based on indoor/outdoor use and seasonal needs.

Choose from our standard styles or send us your custom shape. We support OEM/ODM slipper projects with flexible tooling options.

Select logo methods like heat transfer, cold patch, or injection. Customize packaging for retail, gifting, or Amazon FBA needs.

Review and approve a sample before mass production. We handle QC, packing, and delivery to your destination port or warehouse.

Summer slippers made from EVA, PVC, or rubber often feature printed or transferred logos to boost brand visibility and product value.

Whether you need heat-resistant logos for rubber soles, or seamless branding on EVA molds, we offer a full range of logo applications tailored for seasonal demands.

Clean Finish, Permanent Marking

Laser engraving burns the logo directly into the slipper’s surface for a precise and non-removable effect.

Easy Application, Color Flexibility

Cold patching applies a pre-printed logo film using adhesive. Great for multicolor or gradient designs.

Cost-Effective, Widely Used

Transfers ink via silicone pad, ideal for curved areas like slipper straps, sides, or molded surfaces.

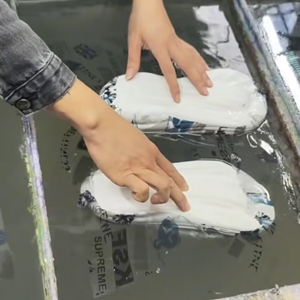

All-Over Coverage, Vibrant Patterns

Printed film floats on water and wraps onto the surface, allowing seamless logo or pattern transfer.

Winter slippers made from fleece, faux wool, or knit uppers require soft-compatible logo methods to preserve warmth and comfort without damaging materials.

From washable labels to embroidery and ink-based printing, we provide logo solutions that withstand daily wear, repeated washing, and low-temperature conditions — ideal for cozy seasonal products.

Soft Touch, Durable Result

Thick ink is screen-printed on fabric uppers, offering a flexible, matte finish.

Premium Look, Long-Lasting Branding

Threads stitched into the fabric create a textured, high-end logo.

Discreet, Practical Branding

Small woven or printed labels sewn inside or beneath the strap.

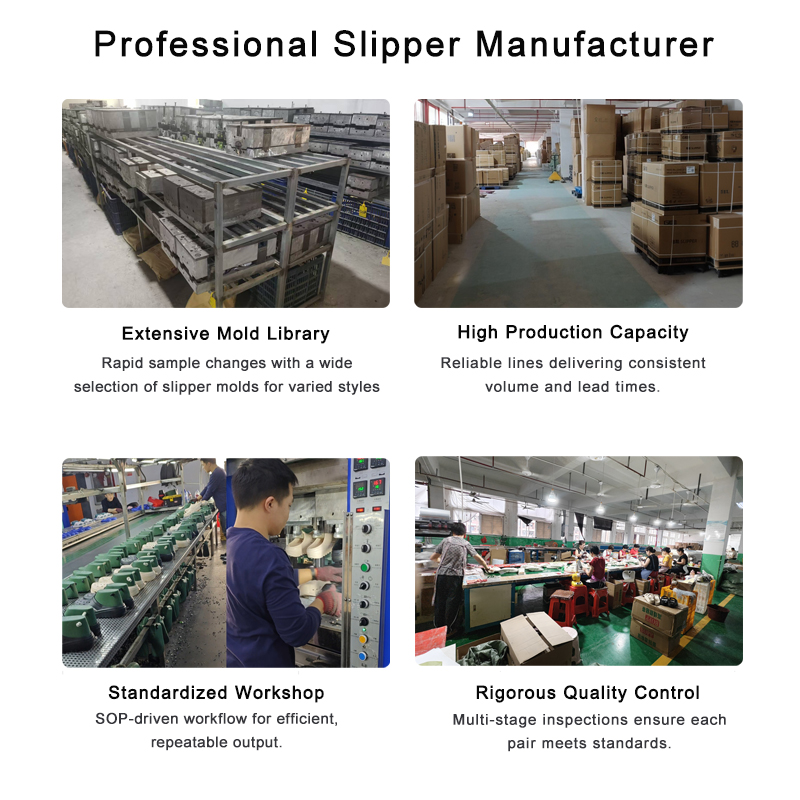

From raw material shaping to final touches, our workshop brings every detail to life — ensuring consistency, comfort, and quality in every pair.

📏 We offer standard sizing charts covering US, EU, UK, and CM measurements. Custom molds and size grading available upon request for OEM/ODM clients.

| US Size | EU Size | UK Size | Foot Length (CM) | Foot Width (CM) |

|---|---|---|---|---|

| 6 | 38 | 5.5 | 23.5 | 8.8 |

| 7 | 39 | 6.5 | 24.5 | 9.0 |

| … | … | … | … | … |

🧷From eco-friendly polybags to customized gift boxes, we offer various packaging options to meet shipping and branding needs. Private labels, barcodes, and inserts supported.

We are happy to receive your letter. Please use the form on the other side to send us an email, and we will reply to you within 24 hours.

© 2025 Vormea | Operated by Fuzhou Shuaiwen Trading Co., Ltd. All Rights Reserved.

WhatsApp us

Tell us your requirements — we reply within 12 hours.

Prefer WhatsApp? Contact us: +86 18065981600

Tell us your requirements — we reply within 12 hours.

Prefer WhatsApp? Contact us: +86 18065981600